SENTRIGARD Metal Roofing

Revolutionizing Contractor-Manufactured Metal Roofing

For All Commercial and Residential Applications

Elevate the Beauty and Durability of your Roof

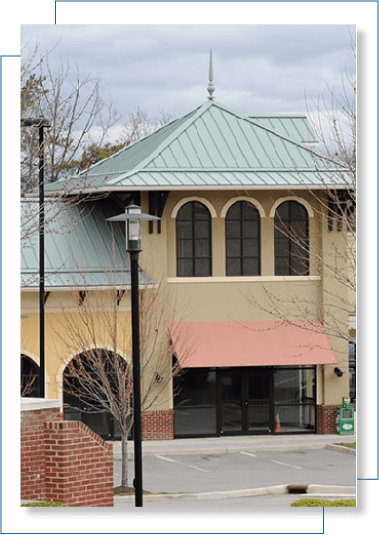

When commercial metal roofing projects are properly executed, the results are lasting beauty with little maintenance. The wrong choice of roofing material can make the difference between a successful job and tremendous problem. Our extensive product knowledge and industry expertise bring value to every project. We offer a complete line of architectural metals and accessories including Sentrigard Metal Roofing Systems, SentriClad coil and sheet, copper coil and sheet, stainless steel and more

From residential to commercial, and from architectural to structural, Sentrigard Metal Roofing Systems meet the challenge for most types of building designs. Sentrigard systems feature panel assemblies that meet the most stringent testing requirements and ensure long-term performance.

For all your commercial or residential metal roofing needs please feel free to contact Commonwealth Exteriors at (540) 505-2084 anytime.

What can SENTRIGARD do for You?

Curb Appeal: Choose from 31 different colors from Sentriclad architectural metals; custom colors are available upon inquiry.

Durability: Finish is a premium baked-on coating specifically designed to meet the functional and aesthetic requirements of many architectural, industrial, and commercial construction applications

Weather Resistance: Finish coating is a 70% PVDF Resin Paint System that is applied to the metal substrate on a continuous, reverse roll coat paint line.

Energy Efficiency: Sentriclad can be incorporated into LEED specified architecture, has earned the ENERGY STAR designation, and is available in Cool Colors

Peace of Mind: Sentriclad finish carries a 30-year limited warranty

Quality Materials: Metal substrate availability includes GALVALUME (AZ50) steel and 3000 series aluminum, and primary gauges include 24 ga GALVALUME and 032, 040 aluminum

SENTRIGARD Roof Panels

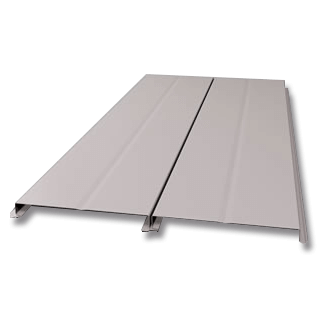

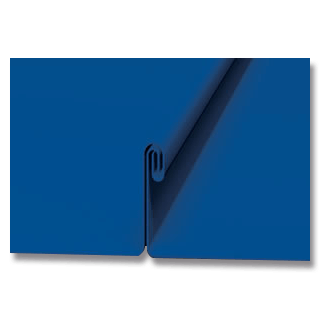

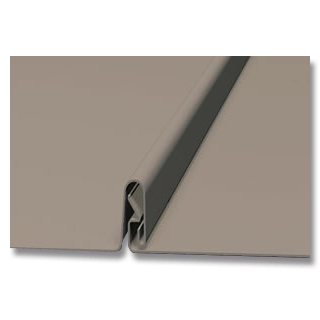

FP100 1 Interlocking Flush Panel

1" Interlocking Flush Panel; max width 15.5"; concealed, interlocking seams fastened with 2 #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; fastening metal to panel to Wood or Steel Substrate; maximum 12" fastener spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Oil Canning is a characteristic of light gauge architectural metals and is not a flaw and therefore is not a cause for rejection.

Download Brochure

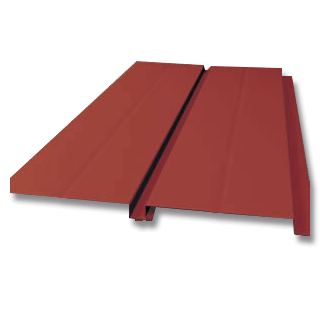

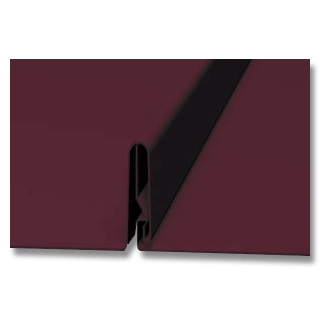

FPR100 1 Flush Panel w/Reveal

1" Flush Panel with Reveal; max width 14.0"; concealed, interlocking seams fastened with (2) #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; fastening metal to panel to Wood or Steel Substrate; maximum 12" fastener spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Oil Canning is not a Cause for Rejection

Download Brochure

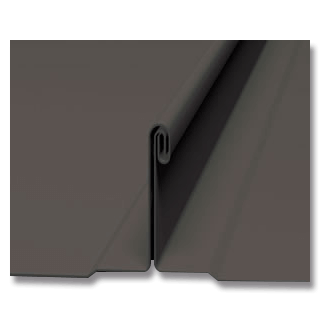

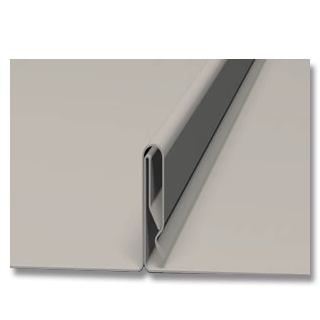

ML100 1 Mechanical Lock Panel

1" Mechanical Lock Panel; max width 17.25"; Double Lock 180 Degree Seam fastened with (2) #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; One Part Clip Assembly ML100R Clip fastening metal to panel to min. 15/32" plywood decking; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -71.0 psf Main Field @ 24" Clip Spacing; Perimeter and Corner Pressure -138.5 psf @ 6" Clip Spacing

Download Brochure

ML150 1 Mechanical Lock Panel

1-1/2" Mechanical Lock Panel; max width 16.3"; Double Lock 180 Degree Seam fastened with (2) #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; Floating Clip Assembly ML150R Clip fastening metal to panel to min. 15/32" plywood decking; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -59.75 psf Main Field @ 24" Clip Spacing; Perimeter and Corner Pressure -123.5 psf @ 6" Clip Spacing; Oil Canning is a characteristic of light gauge architectural metals and is not a flaw and therefore is not a cause for rejection.

Download Brochure

ML200 2 Mechanical Lock Panel

2" Mechanical Lock Panel; max width 18.75"; Double Lock 180 Degree Seam fastened with (2) #12/14 Quadrex drive pancake head, Self Tapping screws; Floating Clip Assembly ML150R Clip fastening metal to panel through Dens Deck Sheathing & Insulation to underlying Steel Decking or over open framing; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Oil Canning is a characteristic of light gauge architectural metals and is not a flaw and therefore is not a cause for rejection.

Download Brochure

NS100 1 Nail Strip Panel

1" Nail Strip Panel; max width 15.79"; Snap Lock Seam fastened with #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws fastening metal to panel to min. 15/32" plywood decking; maximum fastener spacing panel slots; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -59.75 psf Main Field @ 16" Fastener Spacing in Panel Slots; -101.0 psf Perimeters @ 6-3/4" Fastener Spacing in Panel Slots; -153.5 psf @ 6-3/4" Fastener Spacing in Panel Slots & 12 OC in Pan; Oil Canning is a characteristic of light gauge architectural metals and is not a flaw and therefore is not a cause for rejection.

Download Brochure

NS150 1 Nail Strip Panel

1.5" Nail Strip Panel; max width 14.8"; Snap Lock Seam fastened with #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws fastening metal to panel to min. 15/32" plywood decking; maximum fastener spacing panel slots; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -78.5 psf Main Field @ 11" Fastener Spacing in Panel Slots; -116.0 psf Perimeters & Corners @ 6-3/4" Fastener Spacing in Panel Slots & 12 OC in Pan; Oil Canning is a characteristic of light gauge architectural metals and is not a fl aw and therefore is not a cause for rejection.

Download Brochure

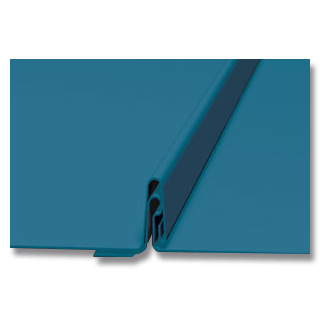

SL100 1 Snap Lock Panel

1" Snap Lock Panel; max width 16.89"; Snap Lock Seam fastened with (2) #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; One Part Clip Assembly SL100R Clip fastening metal to panel to minimum 15/32" plywood decking; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -67.3 psf Main Field @ 24" Clip Spacing; Perimeter and Corner Pressure -131.0 psf @ 6" Clip Spacing; Oil Canning is a characteristic of light gauge architectural metals and is not a fl aw and therefore is not a cause for rejection.

Download Brochure

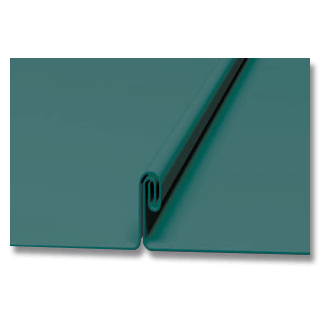

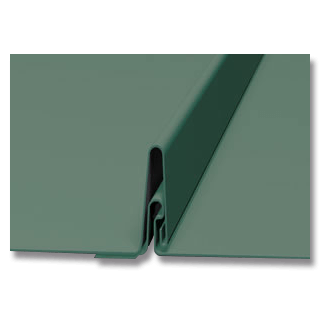

SL150 1 Snap Lock Panel

1-1/2" Snap Lock Panel; max width 15.39"; Snap Lock Seam fastened with (2) #10-12 x 1" long No. 2 Phillips drive pancake head, wood screws; One Part Clip Assembly SL150R Clip fastening metal to panel to minimum 15/32" plywood decking; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Maximum Allowable Roof Uplift Pressure (steel): -86.0 psf Main Field @ 24" Clip Spacing; Perimeter Pressure -108.5 at 12" Clip Spacing; Corner Pressure -116.0 psf @ 6" Clip Spacing; Oil Canning is a characteristic of light gauge architectural metals and is not a fl aw and therefore is not a cause for rejection.

Download Brochure

SL175 1 Snap Lock Panel

1-3/4" Snap Lock Panel; max width 17.625"; Snap Lock Seam fastened with (2) #12/14 Quadrex drive pancake head, self tapping screws; One Part Clip Assembly SL175R Clip fastening metal to panel through Dens Deck Sheathing & Insulation to underlying Steel Decking or open framing; maximum 24" clip spacing; Panel Rollformer: Schlebach Quadro-Plus Rollformer; Oil Canning is a characteristic of light gauge architectural metals and is not a fl aw and therefore is not a cause for rejection.

Download Brochure

On-site Fabrication: Bringing the Solution Closer To The Job

The ability to take manufacturing to the jobsite has become critical for efficient metal roofing fabrication and installation. Sentrigard Metal Roofing Systems offer the flexibility to produce all panels at your facilityor the jobsite. For more information on Sentrigard's On-site fabrication and warranties download the documents below or contact Commonwealth Exteriors anytime.